Hahaha, i am not sure if you are making fun of me or not, but its truly how i felt, i felt like it was a major achievement, considering that i pretty much rebuilt the whole machine, i am very proud of myself, and what i am even more proud of is how everything works perfectly once these tiny details got worked out,

Its true, if you follow these guys lead you will end up with some of the best working equipment around.

i am very excited to be part of the what i consider Elite group of people who own the best Laser Controllers, i am sure there is bigger and better stuff out there but for what a person as a hobby/ small business, you could not for ask any more.

Now for the next two month i will fine-tune and brush up on all my Engineering Design skills, plus learn in depth about physical properties of acrylic and plywood, and once i am comfortable i will sell my DSP K40 and Start on a either 900 x 600 mm or 600 x 400 mm depending on how these two month play out. Mainly all replies on the what my community/ customer base will request as per the item size they would like to create, for me the larger is better, but if i have only 10% of people requiring larger stage, then it is not Cost Effective nor reasonable for me to have anything like that, especially how huge it is.

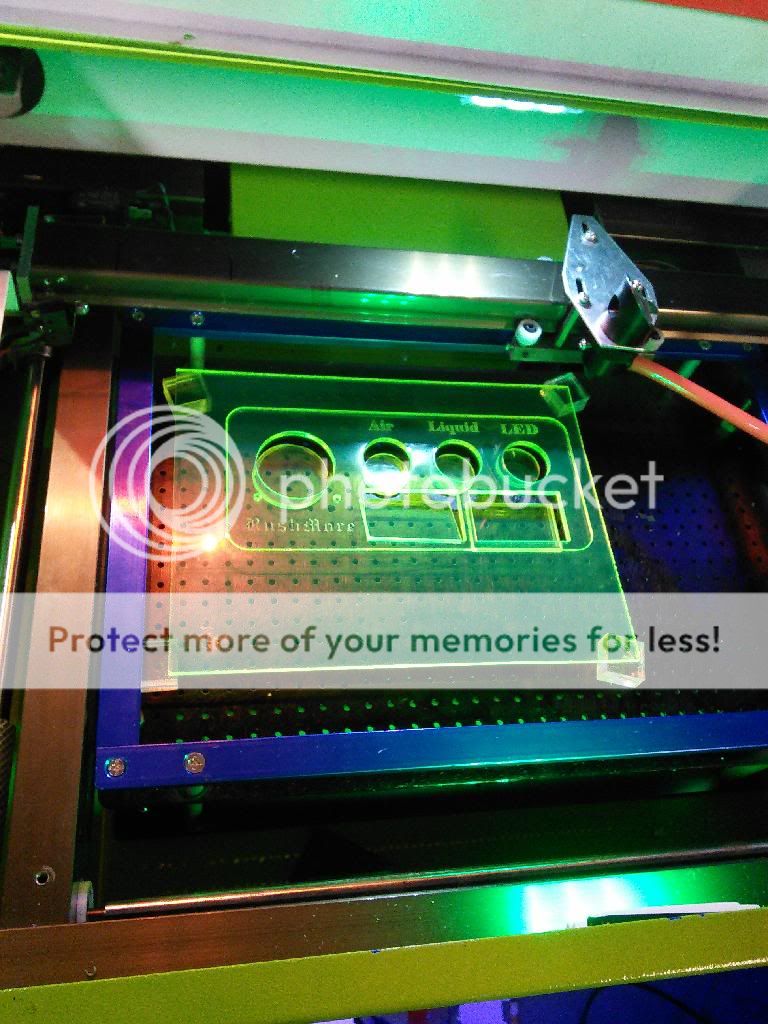

Also would like to Show the now 100% Fully Functional, Mirrors and Lens Aligned and running at Perfect Power, just overall to my standard Superb Laser Machine, this is no longer a "Cheap Chinese Laser Engraver", this is a "40 watt DSP Laser

CUTTER"

Now i am sure everyone here is just like me, so you know that this is still far from over, all though the machine is fully functional, i am going to better it

this Monday to be completed:

1.Z-Bed Control via DSP controller

2.Upgrade the Focus Lens to the best one Light Object sell with 68.5 mm focus distance.

3.Upgrade the Smoke Exhaust System to a much better specialty Exhaust Fan that will be located outside with over 250 CFM, also install the new bracket for the exhaust on the laser which will allow to access the Laser compartment and create an air tight seal around the bracket with Silicone

4. Install the New Air Assist Silicone Line that is a lot larger and better flexing tube, more commonly used by everyone, the line i am using right now is way small making my little pump overheat (mainly because i don't have the proper connector to go to the regulator so i have to go straight to pump, but all that resolved once receive the new tubing)

Outstanding Things/Issues to be Purchased/Brainstormed on Monday:

1. Work on Better Laser Cooling System:

a.) Rewire the Liquid Cooling Tower(works fine as is, but the wiring was sloppy and used terminal with just bare wires, i have Crimp on adapters for the wires for those terminals. just make the whole set up much cleaner looking and eliminate accidents with Shorts or anything like that.

b.) Relocate the Temperature Read-out to the main Control Door(where the DSP Remote is connected to and emergency shut off,pictured below).

c.) Relocated all Three Liquid Cooling Switches to the Main Control Door. that way all the needed safe features are in one location, so that if anyone ever uses the machine that will be in front of everything they possibly need.

d.) Create a new Plate to Lay on top of the Main Control Door with nice rounded edges, because the new DSP remote bracket that i just cut is under the door because our metal is already nicely cut, i am not going to be able to get it as nice so i will make my acrylic nice, and what ever is under it, i can butcher to pieces, if you know what i mean. now depending on my drawings of how much room all this craziness is going to take i might add these two digital voltage meters make sure that my power supplies are not acting up at any point, add one for the motor power supply which is the 24 V, and then my water cooling set up is on a separate 12 V power unit, since i already have the little digital screens why not, throw it in there.

2. Install the Analog mA meter that originally came with the "cheap k40 Chinese laser engraver". Mainly doing this as a piece of mind for security knowing that i am at no point going to be doing harm to the laser, and who ever is around it.

3. Order two of the best 18 - 20 mm Reflection Mirrors from Light Object, after attempting to clean the mirrors with Alcohol today, i discovered that Mirror 1( closest to Laser Tube) has a huge burn mark almost smack in the middle of itself, i was unable to remove it, then had a buddy come look at it and he too came to conclusion that should be replaced. so might as well replace all three, and just buy one standard one, so when i do sell this laser i can sell it with the original mirrors but in perfect condition, because the other two mirrors might as well be brand new.

4. Finally last but not least start thinking about the mounting of the Honey Comb design, that i abandoned in the very begging of me getting into the laser machines. right now 15mm stand offs work great but it will be nice not to have the cut fall out incase i still want to engrave something

Tech_Marco wrote:Congradulation! How you feel now? Did you remember what I told you before? During the procesing of upgrading, you would encounter so many issues and many times you may got frustration. But once you overcome it, it is considered a major break through of each problem solved. And now, you should be proud of yourself being able to complete the proejct. My tears off for you, great job!

When will you have your 'gradulation' ceremony?

Marco