Page 1 of 1

Cornering speed problem

Posted: Mon Mar 28, 2016 3:43 pm

by Agent Sevan

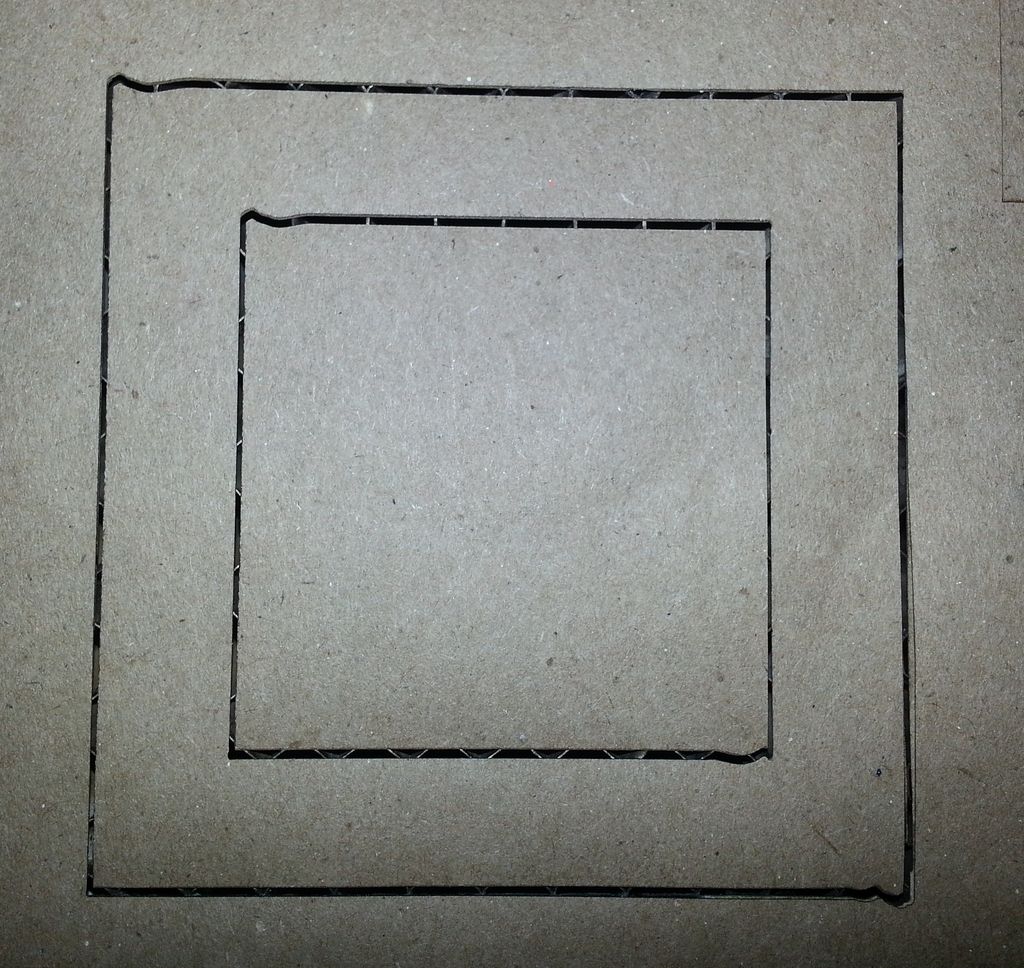

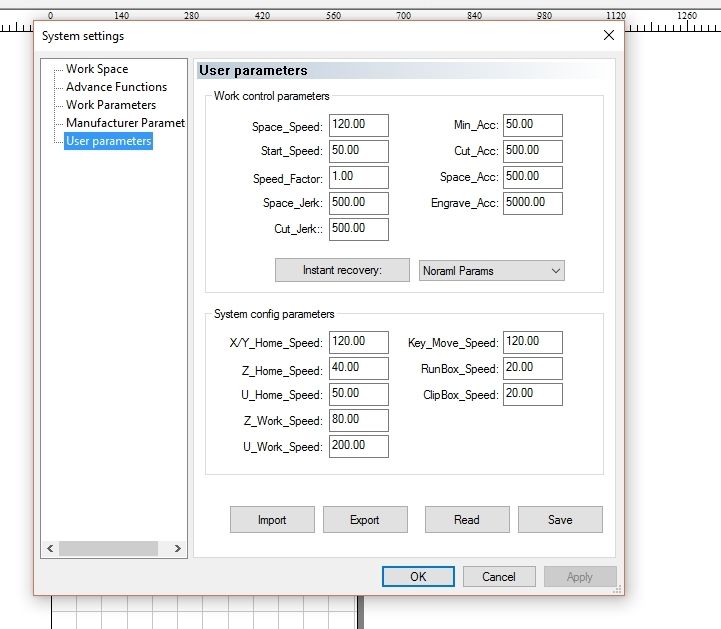

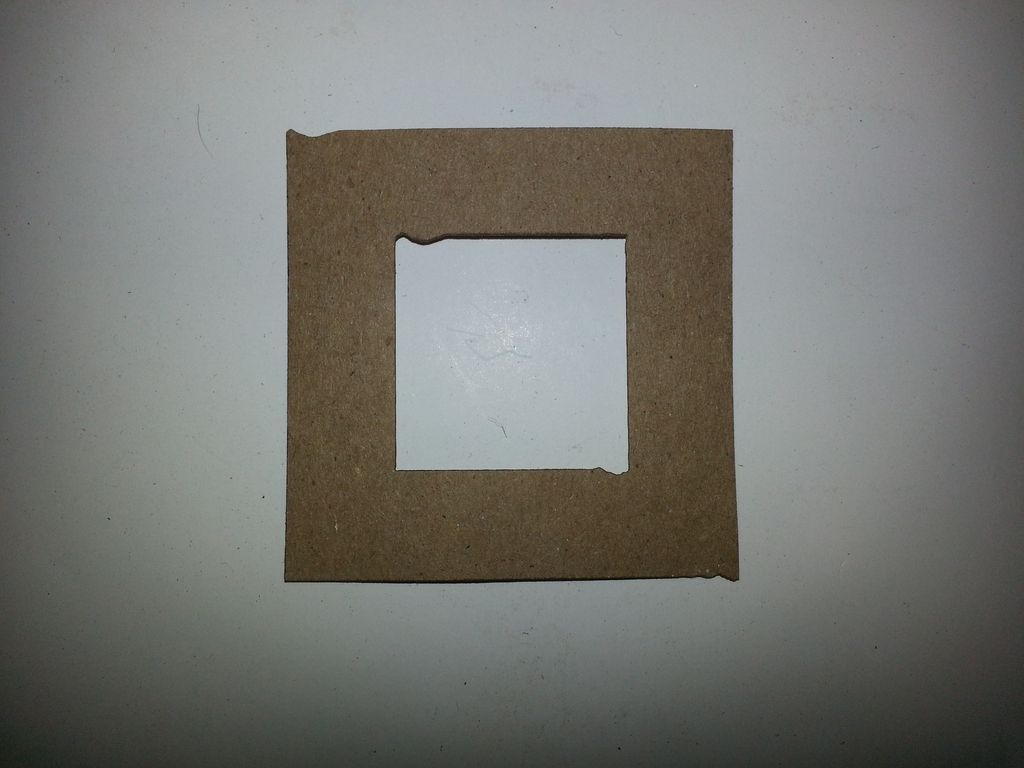

Attached is an example photo of what should be a square. As you can see it outruns one of the axes. That was cut at 25mm/sec. I've tried adjusting the space and cut jerk and turned down the speed factor and cut acceleration but i get the same results whether I'm cutting at 25mm/sec or 60mm/sec and no difference comes from adjusting the settings I mentioned.

Belts are also on tight

Any advice?

Re: Cornering speed problem

Posted: Mon Mar 28, 2016 5:00 pm

by Tech_Marco

Before I can make suggestion:

Post your machine information

Post DSP User Parameters

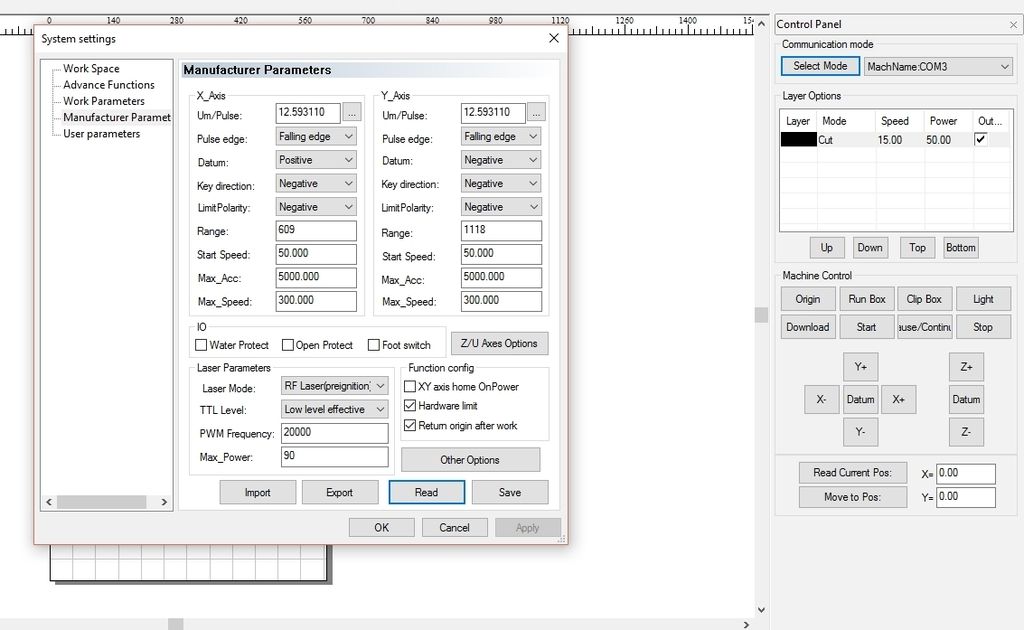

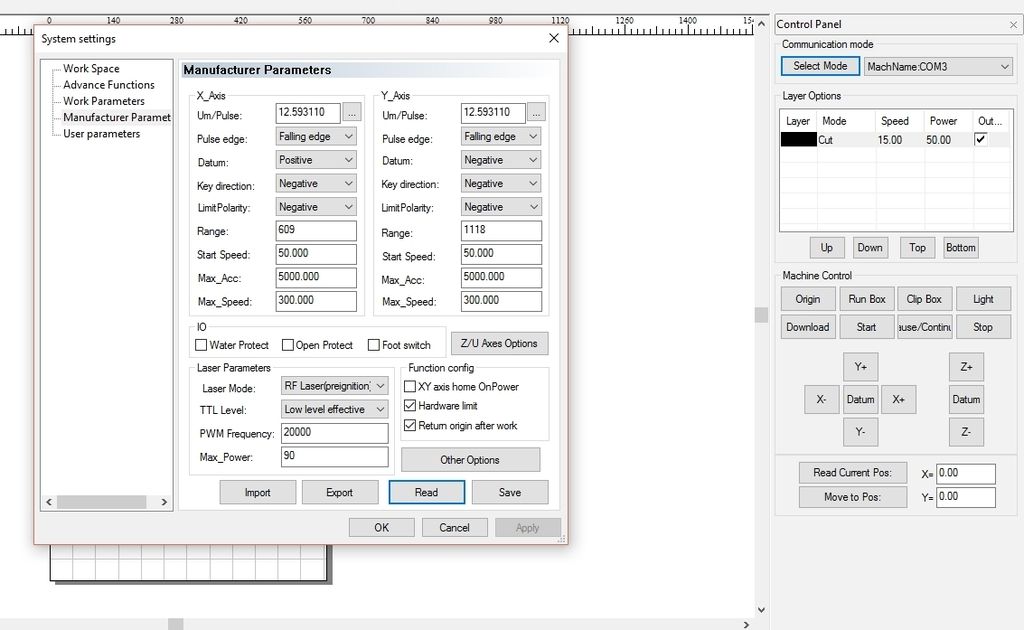

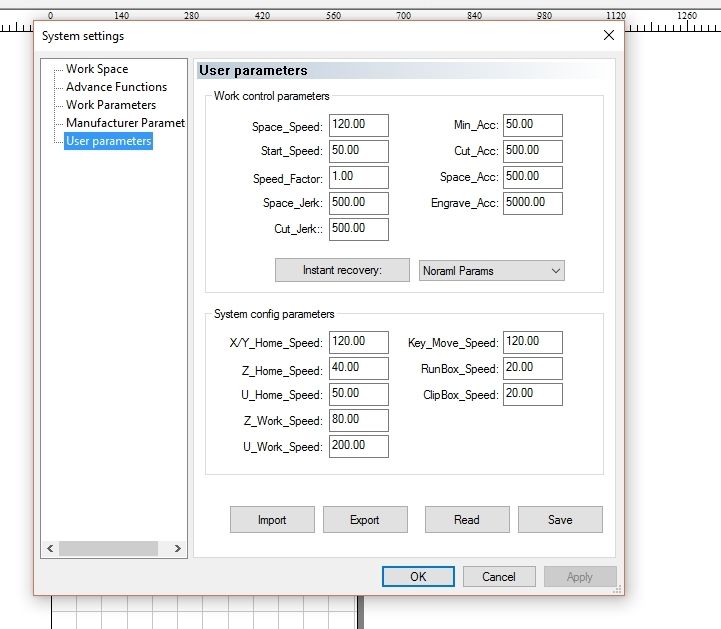

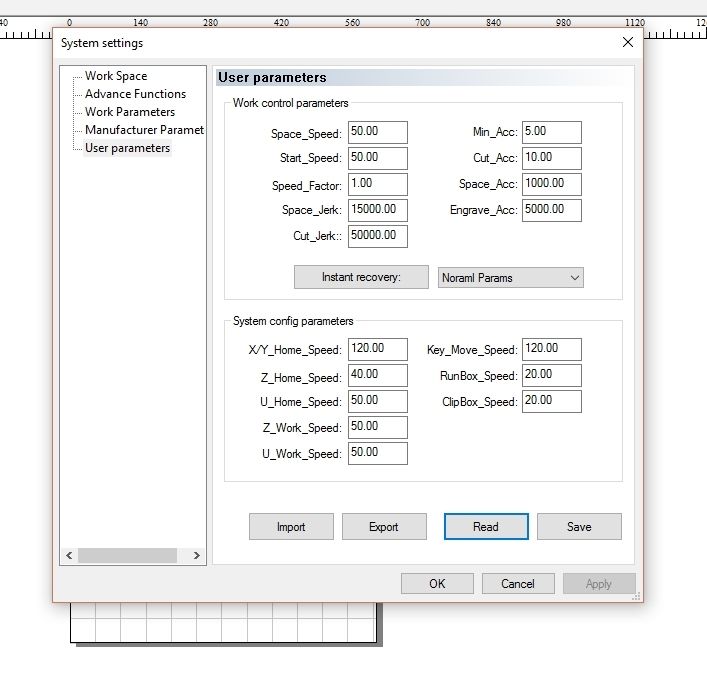

Post DSP Manufacturer Parameters

Marco

Re: Cornering speed problem

Posted: Mon Mar 28, 2016 5:51 pm

by Agent Sevan

Awc608 controller. Leadshine MD882 stepper drivers, Leadshine 57hs22 stepper motors. The laser is a Universal 60 watt water cooled tube RF laser.

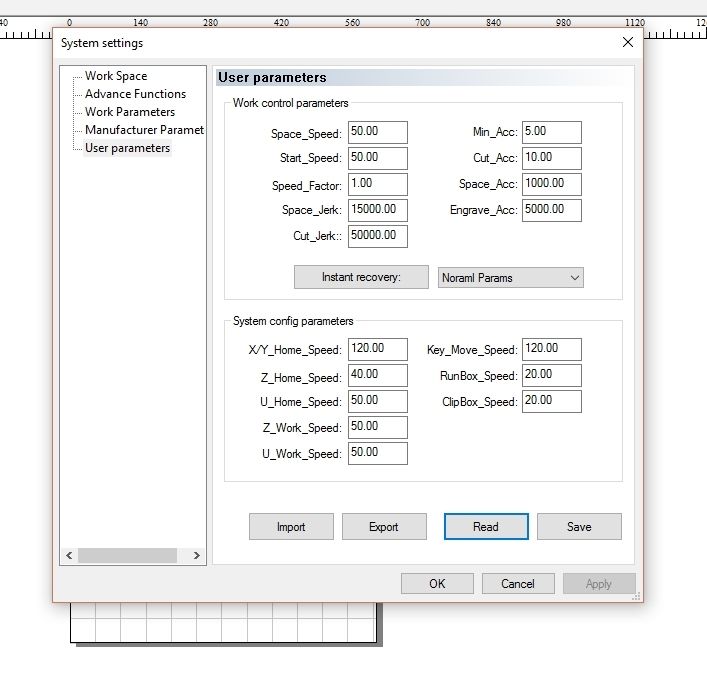

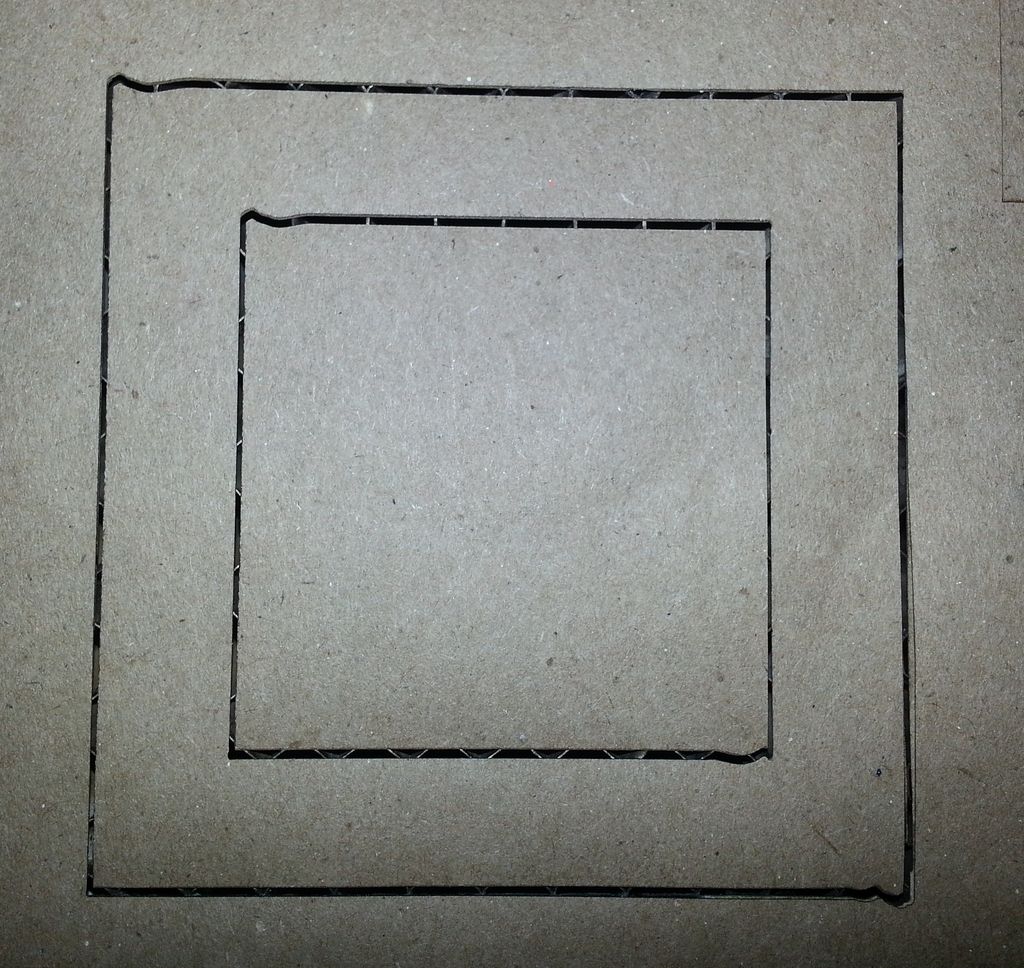

I've had a very curious issue with the user parameters where I will read then save new settings.... then when I go to read again it shows the previous settings and not what I saved.

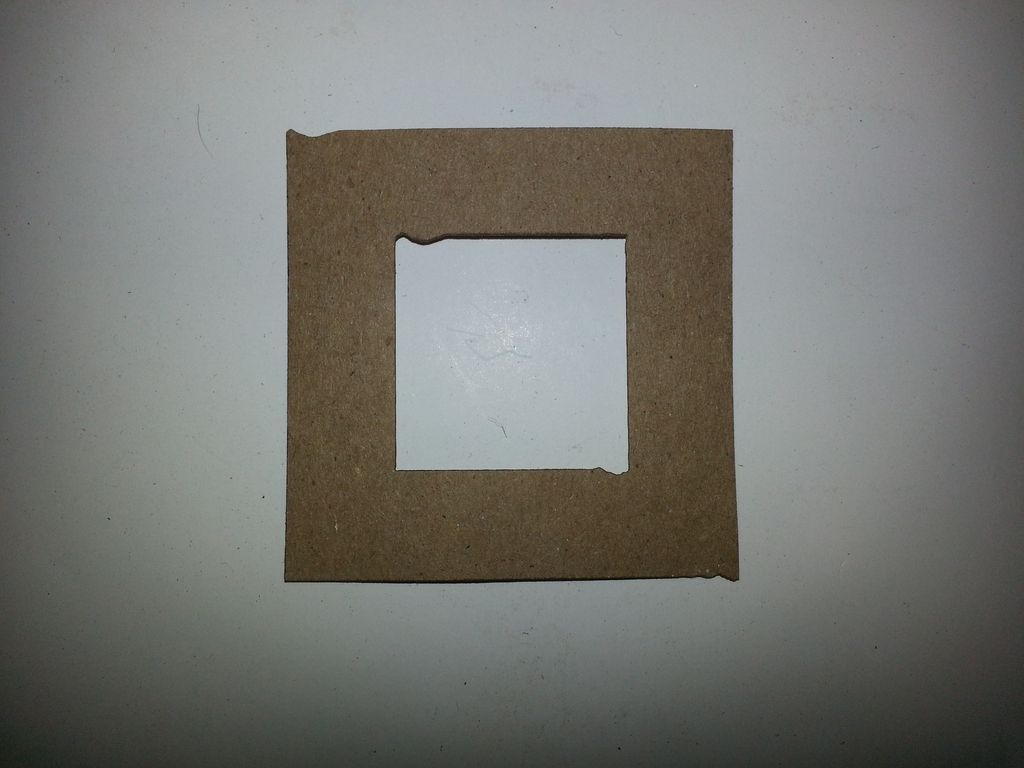

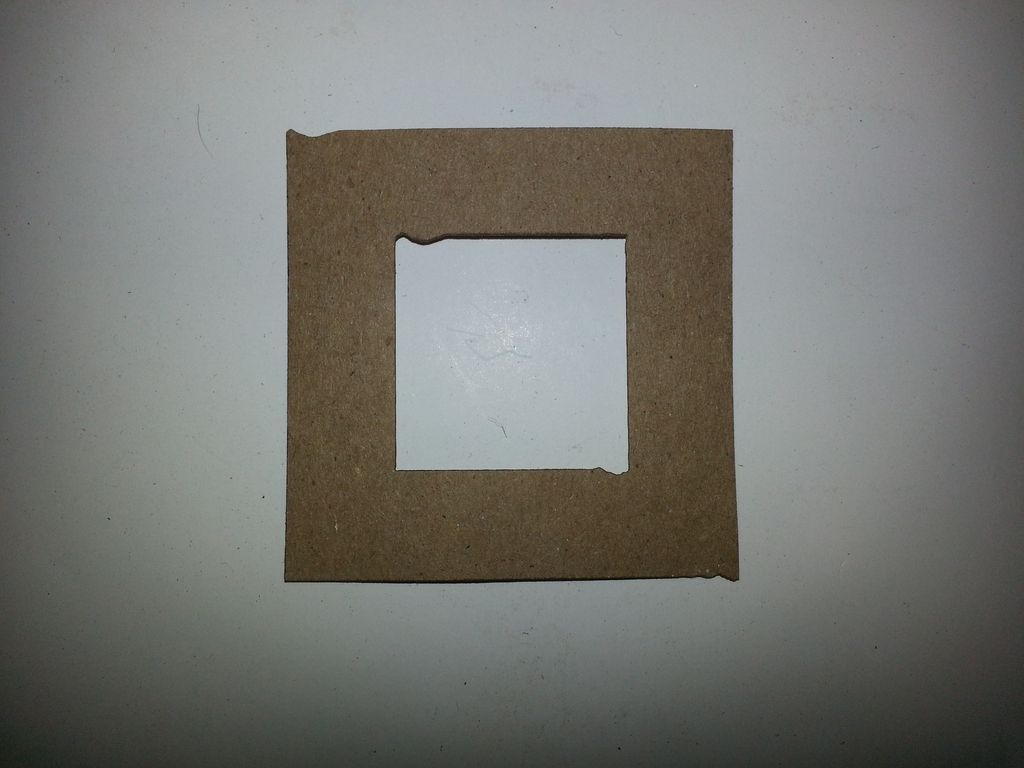

The attached photos are

1. Manufacturer parameters.

2. User Parameters as I have saved them

3. User parameters as they appear after I press "Read"

This is with the controller turned on and connected to my computer.

Re: Cornering speed problem

Posted: Mon Mar 28, 2016 6:10 pm

by Tech_Marco

I think your machine is "undershoot" because acceleration were set too slow on User Parameters.

If your machine isn't a bulky machine like those tube ride on type, you should never set Cut_acc or Space_acc under 2000

Plus, the Cut_Jerk and Space_Jerk should set to 50,00p and 30,000 or bigger number unless you have a very big machine. Even our 2500x1400, I set 18,000 and 15,000 respectively

Marco

Re: Cornering speed problem

Posted: Tue Mar 29, 2016 4:11 am

by Agent Sevan

My Y axis does move some weight around... 1200mm x 1200mm table with metal honeycombs.

So what do settings do you recommend I try next?

Re: Cornering speed problem

Posted: Tue Mar 29, 2016 6:00 am

by Agent Sevan

With the settings that you use for your large table (18,000, 15,000, 2,000 and 2,000 this is my result. Same thing.

If I use the default faster or fastest params the stepper motors just bind and grind.