Page 4 of 6

Re: Rookie at Laser, NEED stupid questions answered

Posted: Thu Oct 03, 2013 6:23 pm

by rushmore1305

Tech_Marco wrote:I can tell you that you will be more happy once you fixed the issue. Being successful the first set things up are great but not the most. Having some 'bumpy road' and you fix the problem one by one is more joyful. Plus, you will be built up a bunch of skill and I'll more happy to give you the graduation hat (We call it square hat

At this time, forget about bad motor or Z table. Focus on the machine is your priority. Usually the motors are good and you better check each wire again. Me sometimes made stupid mistake by making wrong connection on the K40. Looks simple but sometimes a simple thing caused big time!

You don't need to use second power supply for the motors. Just double check the voltage drop on the power supply when the motor is running. If somehow somewhere short circuit happened or not enough current, the voltage will drop dramatically. If something wrong with the motor and if you're driving it by DC24V. When you measure the voltage and found that it is 22V or below, chance is that there is wiring issue! If DC12V drop down to 11V or lower, again something wrong. It could be a faulty power supply. Remember, everything you have done so far are "tools" and you can re-used it. It is what we called "Trouble shooting".

There are two type of DIY folks: Of one type folks are enjoying the most when the project is completed and have a workable product. Another type is that folks enjoying the building process . An excitement won't last long for a completed project so and they moved on to apply modification and enjoy the trouble shooting.

Regardless which type person you're, be patience and enjoy the process. I tell you a story: without too much help from other and no manual, it took me 6 months to learn how to use OrCad PCB program by using the tactic of "Try and error". The Orcard got bunch of parameters and keys. Everyday after work, I spent about 2hrs to test each parameter. After six months testing I got a combination worked out and since then, I could do schematic, parts list, and PCB all in one. SIX months wasn't short right? How long did you spend on your project, two weeks? So, no complain solider, move on!

Marco

lol

you funny guy man, i definatly love the the building aspect of it, as well as trouble shooting, i was just frustrated because i was literary up working 27 hours on this thing lol

non stop.

but yeah it iwll be up and runing shortly

Re: Rookie at Laser, NEED stupid questions answered

Posted: Thu Oct 03, 2013 6:32 pm

by rushmore1305

just so i am clear understanding this, there is no way my limit switches could be the cause of the motors acting up, right?

becasue the motors would move somewhere even if there was no switches correct?

Tech_Marco wrote:I can tell you that you will be more happy once you fixed the issue. Being successful the first set things up are great but not the most. Having some 'bumpy road' and you fix the problem one by one is more joyful. Plus, you will be built up a bunch of skill and I'll more happy to give you the graduation hat (We call it square hat

At this time, forget about bad motor or Z table. Focus on the machine is your priority. Usually the motors are good and you better check each wire again. Me sometimes made stupid mistake by making wrong connection on the K40. Looks simple but sometimes a simple thing caused big time!

You don't need to use second power supply for the motors. Just double check the voltage drop on the power supply when the motor is running. If somehow somewhere short circuit happened or not enough current, the voltage will drop dramatically. If something wrong with the motor and if you're driving it by DC24V. When you measure the voltage and found that it is 22V or below, chance is that there is wiring issue! If DC12V drop down to 11V or lower, again something wrong. It could be a faulty power supply. Remember, everything you have done so far are "tools" and you can re-used it. It is what we called "Trouble shooting".

There are two type of DIY folks: Of one type folks are enjoying the most when the project is completed and have a workable product. Another type is that folks enjoying the building process . An excitement won't last long for a completed project so and they moved on to apply modification and enjoy the trouble shooting.

Regardless which type person you're, be patience and enjoy the process. I tell you a story: without too much help from other and no manual, it took me 6 months to learn how to use OrCad PCB program by using the tactic of "Try and error". The Orcard got bunch of parameters and keys. Everyday after work, I spent about 2hrs to test each parameter. After six months testing I got a combination worked out and since then, I could do schematic, parts list, and PCB all in one. SIX months wasn't short right? How long did you spend on your project, two weeks? So, no complain solider, move on!

Marco

Re: Rookie at Laser, NEED stupid questions answered

Posted: Thu Oct 03, 2013 9:27 pm

by rushmore1305

man i am seriously starting to loose hope here, i have rewired the machine, and still same outcome, they want to move, they sound like theyt want to move but nothing

Re: Rookie at Laser, NEED stupid questions answered

Posted: Thu Oct 03, 2013 9:39 pm

by Tech_Marco

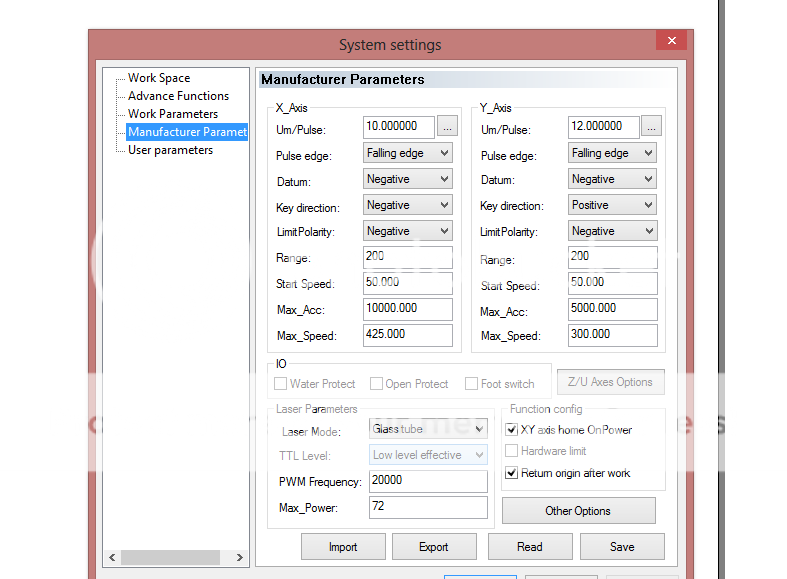

Post the DSP setting see if anything wrong.

Also, what is setting on the motor driver?

Re: Rookie at Laser, NEED stupid questions answered

Posted: Thu Oct 03, 2013 9:41 pm

by rushmore1305

man i am seriously starting to loose hope here, i have rewired the machine, and still same outcome, they want to move, they sound like theyt want to move but nothing

also every time i click reset, the lcd displayes system reseting for a good five minutes every singel time, what could that mean

Re: Rookie at Laser, NEED stupid questions answered

Posted: Thu Oct 03, 2013 9:49 pm

by rushmore1305

Re: Rookie at Laser, NEED stupid questions answered

Posted: Thu Oct 03, 2013 9:59 pm

by rushmore1305

ok thgis is the X

and this is Y

Re: Rookie at Laser, NEED stupid questions answered

Posted: Thu Oct 03, 2013 10:38 pm

by rushmore1305

ok so i actually took out the motor, and when i take power straight to motor, does the motor have to start moving, or just click, because when i take all three cables only to the minus, there is a spark, but the motors just clicks and does not move

Re: Rookie at Laser, NEED stupid questions answered

Posted: Fri Oct 04, 2013 11:18 am

by Tech_Marco

rushmore1305 wrote:ok so i actually took out the motor, and when i take power straight to motor, does the motor have to start moving, or just click, because when i take all three cables only to the minus, there is a spark, but the motors just clicks and does not move

You sure don't want to power the motor by DC direct! Most stepping motors are running at 2.34V and if did that, you may below out the coil. The motor driver provide 'fire wall' by limiting the current to the motor. So, if current set correctly, the voltage is "don't care". But if you hook up DC12V or DC24V to the stepping motor, you could damage the motor.

You may buy a stepping motor and another 2M415 from our site and I'll test it make sure it works. Then you can try it on your setup. That way, we eliminate trouble one by one.I hope that it is not the DSP that caused the trouble. My you never know. Once you hook up the new motor and driver and if it works, that mean the motor you have is bad (or the driver). But it if doesn't work like the one you have, that mean the DSP could be damaged

By the way, both X and Y should have the same (or closed) "um". 10 and 12 is a lot of difference. Use 12.5 on both

Marco

Re: Rookie at Laser, NEED stupid questions answered

Posted: Tue Nov 05, 2013 2:58 am

by rushmore1305

Marko. Thank you for your reply I had to leave country on emergency job trip. Now I'm back. It's sad to see your conclusion but also makes me happy because I thought I was going crazy.

Please link exactly what you think I should buy. That way I don't make stupid mistakes

I'm also afraid it might be the DSP because of the weird long resetting times it goes through. But we Will see once you show me what to purchase

Tech_Marco wrote:rushmore1305 wrote:ok so i

actually took out the motor, and when i take power straight to motor, does the motor have to start moving, or just click, because when i take all three cables only to the minus, there is a spark, but the motors just clicks and does not move

You sure don't want to power the motor by DC direct! Most stepping motors are running at 2.34V and if did that, you may below out the coil. The motor driver provide 'fire wall' by limiting the current to the motor. So, if current set correctly, the voltage is "don't care". But if you hook up DC12V or DC24V to the stepping motor, you could damage the motor.

You may buy a stepping motor and another 2M415 from our site and I'll test it make sure it works. Then you can try it on your setup. That way, we eliminate trouble one by one.I hope that it is not the DSP that caused the trouble. My you never know. Once you hook up the new motor and driver and if it works, that mean the motor you have is bad (or the driver). But it if doesn't work like the one you have, that mean the DSP could be damaged

By the way, both X and Y should have the same (or closed) "um". 10 and 12 is a lot of difference. Use 12.5 on both

Marco

Re: Rookie at Laser, NEED stupid questions answered

Posted: Fri Nov 08, 2013 6:38 pm

by Tech_Marco

I'm in China searching for new products. I won't be able to assist you at this time as Internet access is very limited

How far you're now? Can you get the motor running yet?

Marco

Re: Rookie at Laser, NEED stupid questions answered

Posted: Tue Nov 12, 2013 11:31 pm

by rushmore1305

Tech_Marco wrote:I'm in China searching for new products. I won't be able to assist you at this time as Internet access is very limited

How far you're now? Can you get the motor running yet?

Marco

i am at the exact same spot, cant get the motors to do nothing.

i need to purchase new motors. so let me understand this right, because you are in china what ever i order from your site will not get shipped till you get back? or is there someone who will still dispatch the orders.

all i needed from you if that is the case is to point me to the proper motors i need to replace the existing ones, or maybe some other members can help me out, i just dont want to order the wrong thing and be set back even more then i am now

Re: Rookie at Laser, NEED stupid questions answered

Posted: Tue Nov 12, 2013 11:35 pm

by rushmore1305

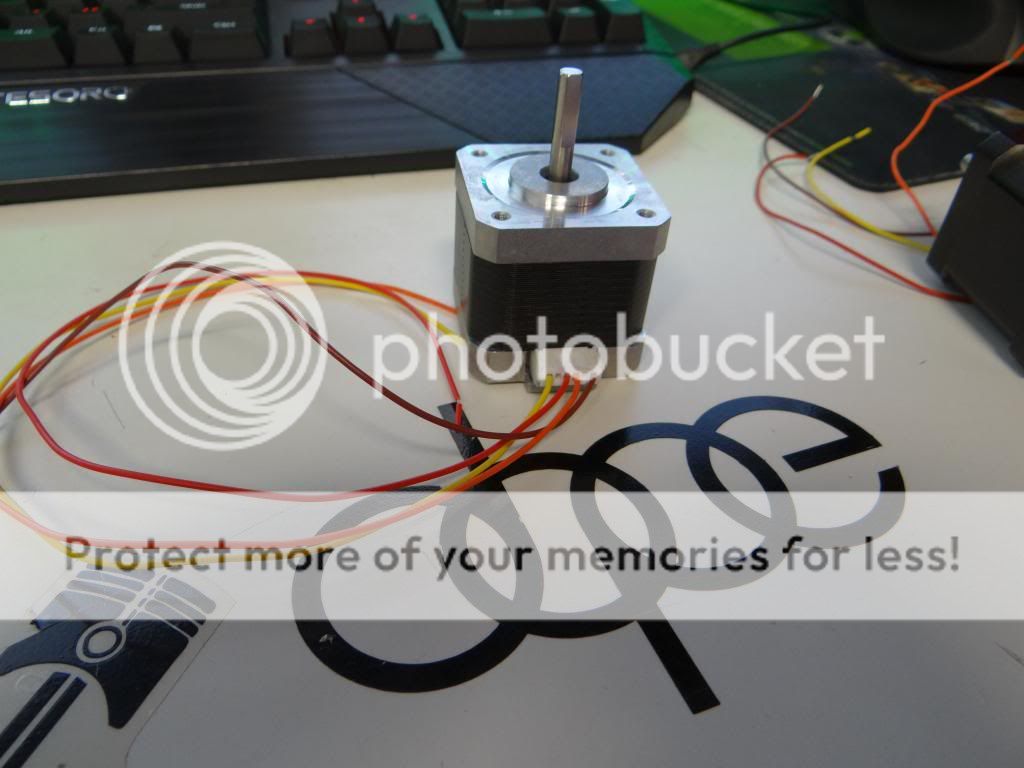

from what i understand is that i have nema 17 motors in the unit, correct.

it looks like this one and this one:

http://www.lightobject.com/NEMA-17-42HS ... -P723.aspx

http://www.lightobject.com/NEMA-17-42HS ... -P747.aspx

Re: Rookie at Laser, NEED stupid questions answered

Posted: Wed Nov 13, 2013 12:43 am

by Tech_Marco

The motors from your post are all good to go.

Evrn thought Im in China, my staffs there in Sacramento will take care your order

Marco

Re: Rookie at Laser, NEED stupid questions answered

Posted: Thu Dec 26, 2013 1:42 pm

by rushmore1305

Tech_Marco wrote:The motors from your post are all good to go.

Evrn thought Im in China, my staffs there in Sacramento will take care your order

Marco

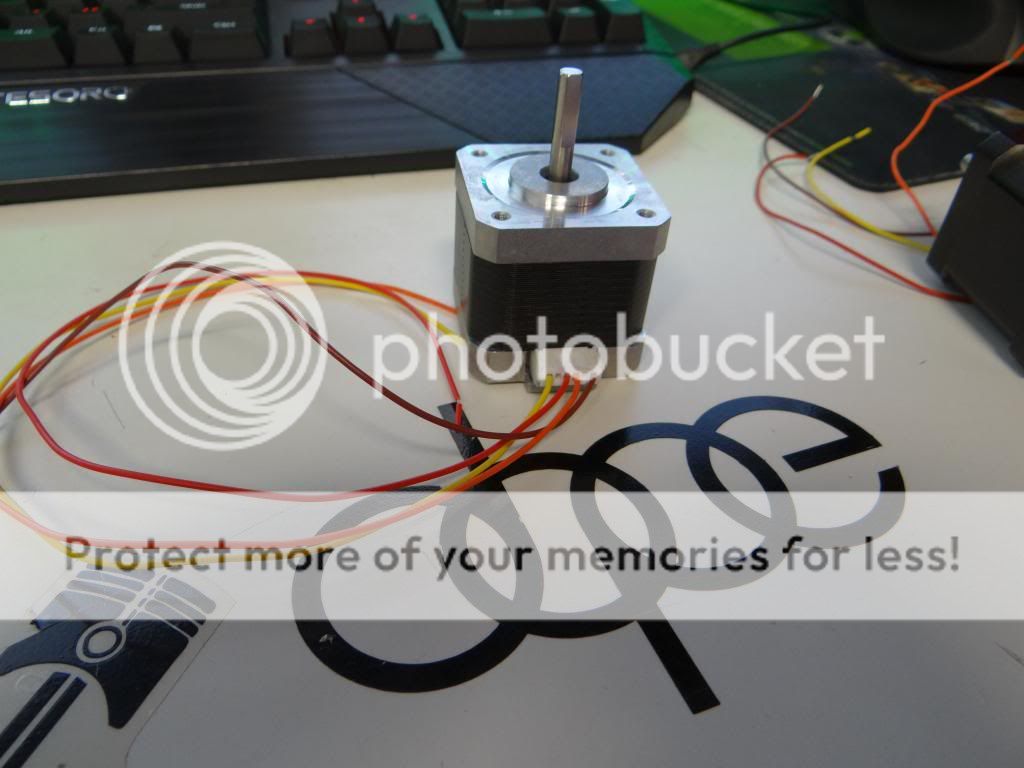

ok thank you for your help so far, so i finaly got back home, and the motors i bought from you are here, i just dont want mess anything up so can you please direct me to the proper Pin/OUT on the motors( what does each color mean)

SO here is what i gathered from you store information please answer the questionmarks, please

X Stage Single Shaft

NEMA 17 42HS02 Stepper motor

NEMA 17 Motor:

Specification:

Step angle: 1.8 deg

Step per revolution: 200

Phases: 2

Single shaft, 5mm

No. wires: 4 or 6 center tag

Current: 0.8A

Holding Torque: 0.32 N.M (45oz*in)

Inductance: 17 mH

Phase resistance: 10 ohms

Detente torque: 150 gcm

Rotor Inertia: 57 g-cm2

Weight: 0.24KG (0.5lb)

Length: 40mm

PIN-OUT: from left to right

YELLOW:???????????

RED: ??????????

ORANGE:?????????

BROWN:?????????

Y Stage Dual Shaft

NEMA 17 42HSM03 Dual Shaft Stepper motor

NEMA 17 Motor:

Specification:

Step angle: 1.8 deg

Step per revolution: 200

Phases: 2

Single shaft, 5mm

No. wires: 4 or 6 central tag

Current: 1.8A

Holding Torque: 0.5 N.M (70oz*in)

Inductance: 4 mH

Phase resistance: 46 ohms

Detente torque: 200 gcm

Rotor Inertia: 82 g-cm2

Weight: 0.34KG (0.75lb)

Length: 48mm

PIN-OUT: from left to right

ORANGE: ??????????

YELLOW: ?????????

BROWN: ??????

RED: ???????