Images belong to: http://www.electricstuff.co.uk

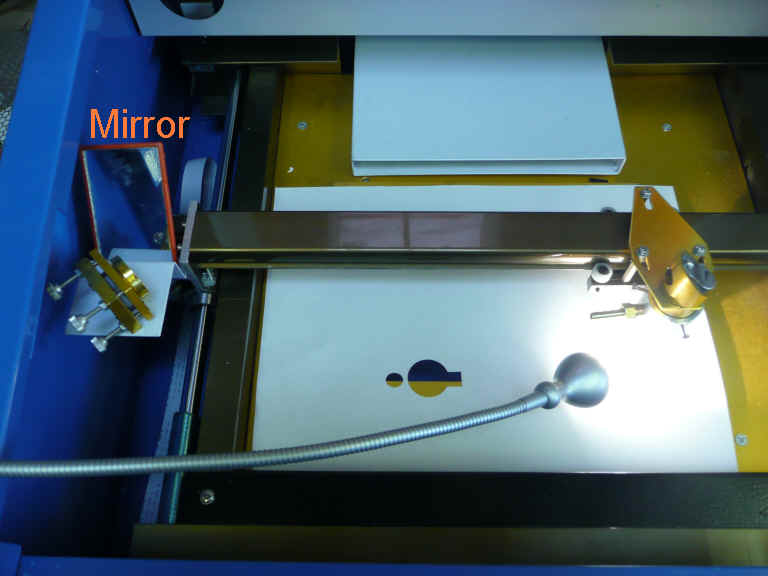

If I put something with small print under the nozzle and look through the mirror I can read the letter clearly by only when the nozzle is physically touching the object. This is also a problem because the tip of the air assist is also essentially the gantry height so it snags the papers edges if not taped down.

Is something wrong here or is this lense too short for this assembly?